The German Tool and Mold Makers’ Association on a high-tech tour in Schmalkalden

«voll wild» is the name of the managing directors’ meeting regularly held by the VDWF. On May 17th, the group visited the Schmalkalden University of Applied Sciences and toolmaking companies in the region. The latest edition of this meeting format also traced the city’s technological history.

A team of 30 of tool and mold making company representatives from German-speaking countries visited Schmalkalden in mid-May to discuss the latest developments in their area of expertise. The city is an important location for tool and mold making due to both the university and the many companies based in the region. Its importance extends back to the Middle Ages the production of iron and steel has been documented there since the 14th century.

From granulate production to 3D printing

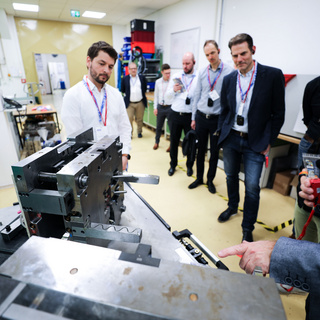

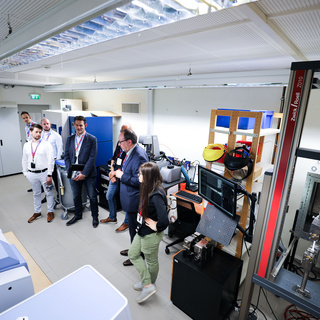

The program began with a reception at the Schmalkalden University of Applied Sciences. As a collaborating partner of the VDWF, the University has been offering six courses in tool and mold making for several years. One of the highlights of the day was the guided tour of the University’s Laboratory for Applied Plastics Technology with Prof. Stefan Roth and Prof. Thomas Seul. Seul explains that «We gave participants some insight into research topics that are currently of great concern to the industry: from material testing and 3D printing to granulate production and sensors in injection molding tools.» In addition to his university professorship, Seul also holds the office of the VDWF President. «The interest was enormous,» adds VDWF Managing Director Ralf Dürrwächter.

A direct look into practice

At the Society for Manufacturing Technology and Development Schmalkalden (the GFE), the focus was on the presentation of hard metal machining tools. During the factory tours at Hehnke and Formconsult, participants looked behind the scenes at the production of tools with micrometer range precision and their application in the manufacturing of high-tech plastic products. The Suppinizer, a product created by the cooperation of Formconsult and the University graduate and body builder Tim Budesheim was also presented. The Suppnizer is a supplement container tailored to bodybuilding needs. Dürrwächter explains that «It was interesting for us to get to know the product development process and to see how a cooperation between a toolmaking company and a start-up can work.»

A city for toolmakers

The program finished with a guided city tour with beer tasting to accompany sights, which was conducted by the Schmalkalden Brewery. Highlights on the tour of course included the landmarked historical old town with its half-timbered buildings and the Luther House, the St. George town church, and Wilhelmsburg Castle. The tour also focused on communicating the city’s technological history: For example, a «furnace pig» measuring almost two meters in diameter and weighing tons is a slag remnant of medieval iron processing which proves that the foundry trade was practiced in Schmalkalden centuries ago. «No wonder toolmakers feel at home here,» says Prof. Thomas Seul, and laughs.